Spark Eroder / EDM machine

Spark Eroder LOTO-eng type SEC-500 version is the right tool to drill the gasket used in experiments in DAC cells.

Made of different materials, such as BeCu Tungsten steel etc. the gasket, after the indenting, can have the thickness from 10 to 100 or more microns.

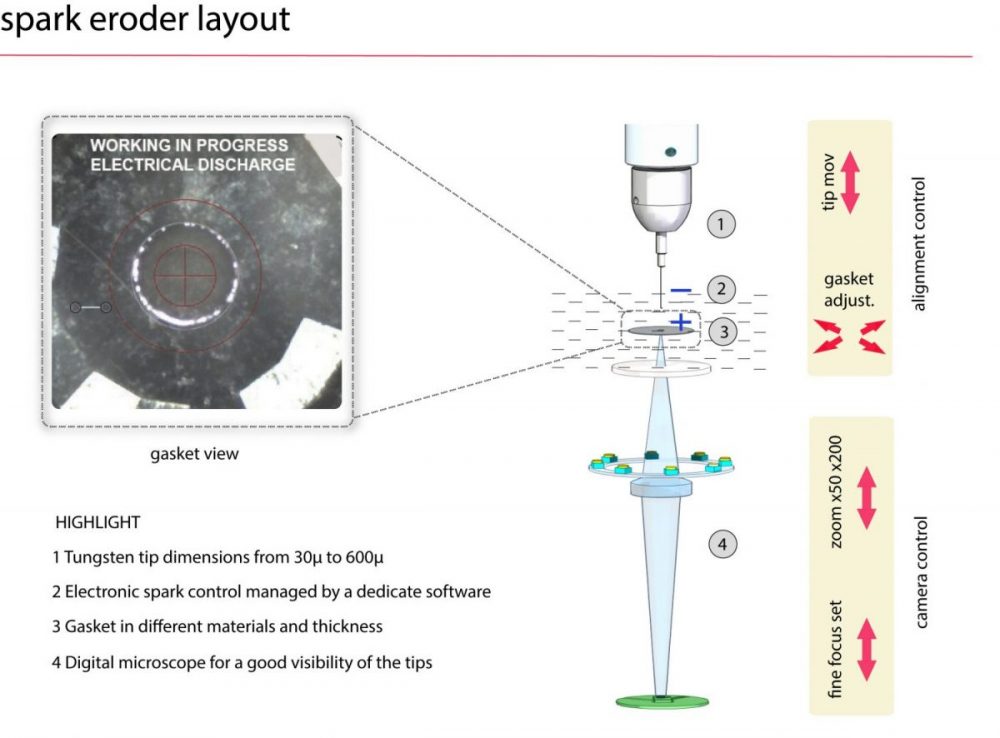

The machine uses an electroerosion process EDM (electro discharge machine) The SPARK Eroder SEC-500 is an automatic tool designed with innovative concepts and solutions. The drilling tip, from 50 to 600 microns, is in Tungsten. The duration and efficiency of the ablation process depend on different factors such as: - power and voltage of the current emitted by the tip - types of materials used for the tip and types of materials for the gasket - type of dielectric liquid.

The EDM machine uses a proprietary and interactive software to manage the advancement of the tip, controlling the discharge level.

Thanks to the feedback circuit, the tip is kept on the gasket, at the right distance to permit the discharge, until the entire drilling process is completed.

The user can easily monitor the entire process thanks to a camera positioned under the work area that sends images to the management software. The software allows to optimize the alignment phase which is essential to have the required hole in the gasket, that is, in the center of the indentation.

The duration and the efficiency of the ablation process depend on several factors which:

– power and voltage of the current emitted from the tip

– types of materials used for the tip and types of materials for the gasket

– type of dielectric liquid used.

TECHNICAL DATA

| DRILLING DIMENSIONS | Holes 50-600 microns |

| DRILLING MATERIAL GASKET | Stainless steel, Rhenium, BeCu, Tungsten, Platinum |

| MAGNIFICATION | 200x and camera software |

| FAST DRILLING | 25 micron/min (related the material and the hole diameter) |

| SOFTWARE | SED-500 Spark Eroder |

| DIMENSIONS / WEIGHT | 240x130x230 mm 5 Kg |

HIGHLIGHT

- Easy to align,

- Save the tip during an accidental straight

- 100%success making the hole

- Software for a smart control