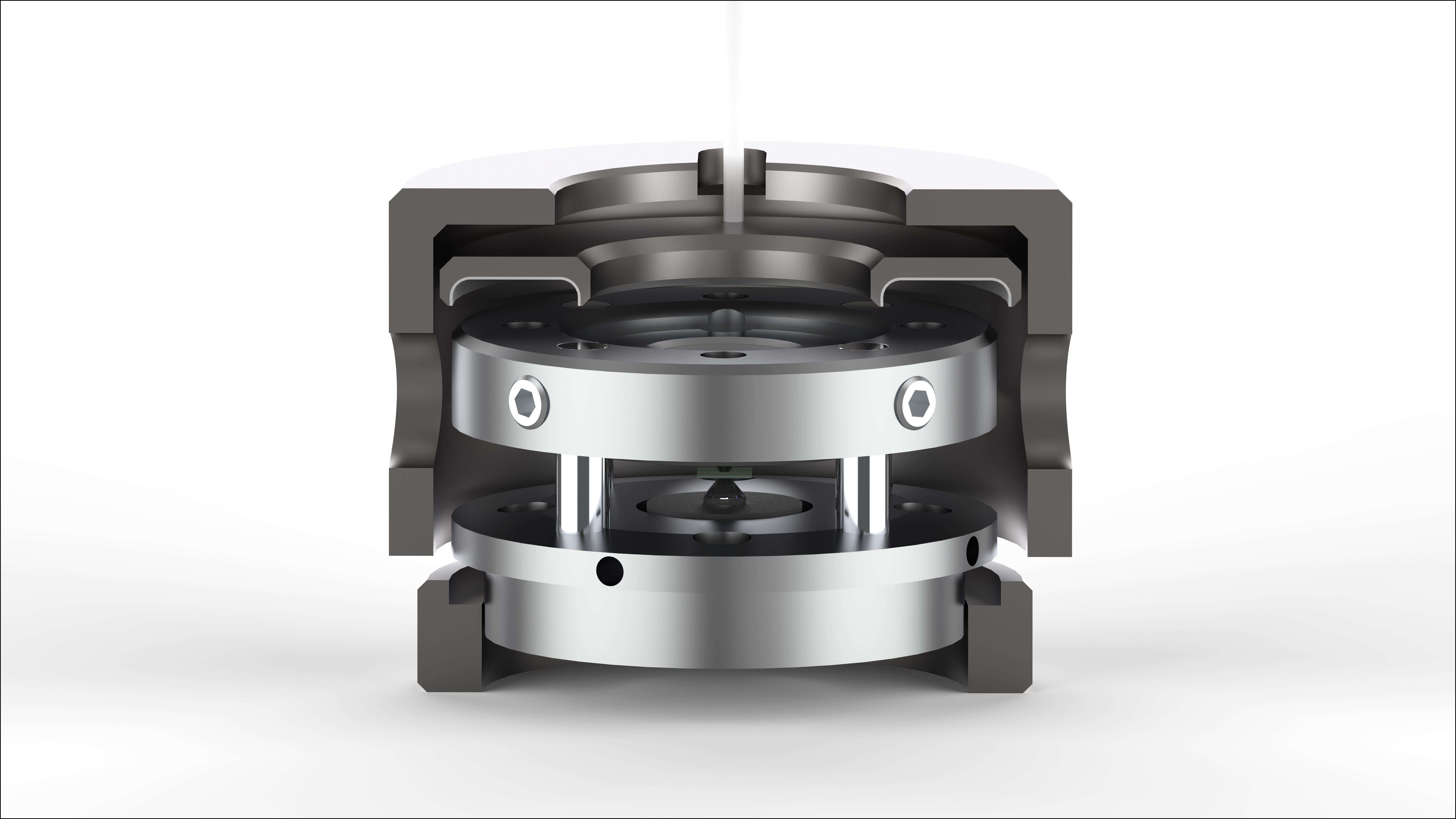

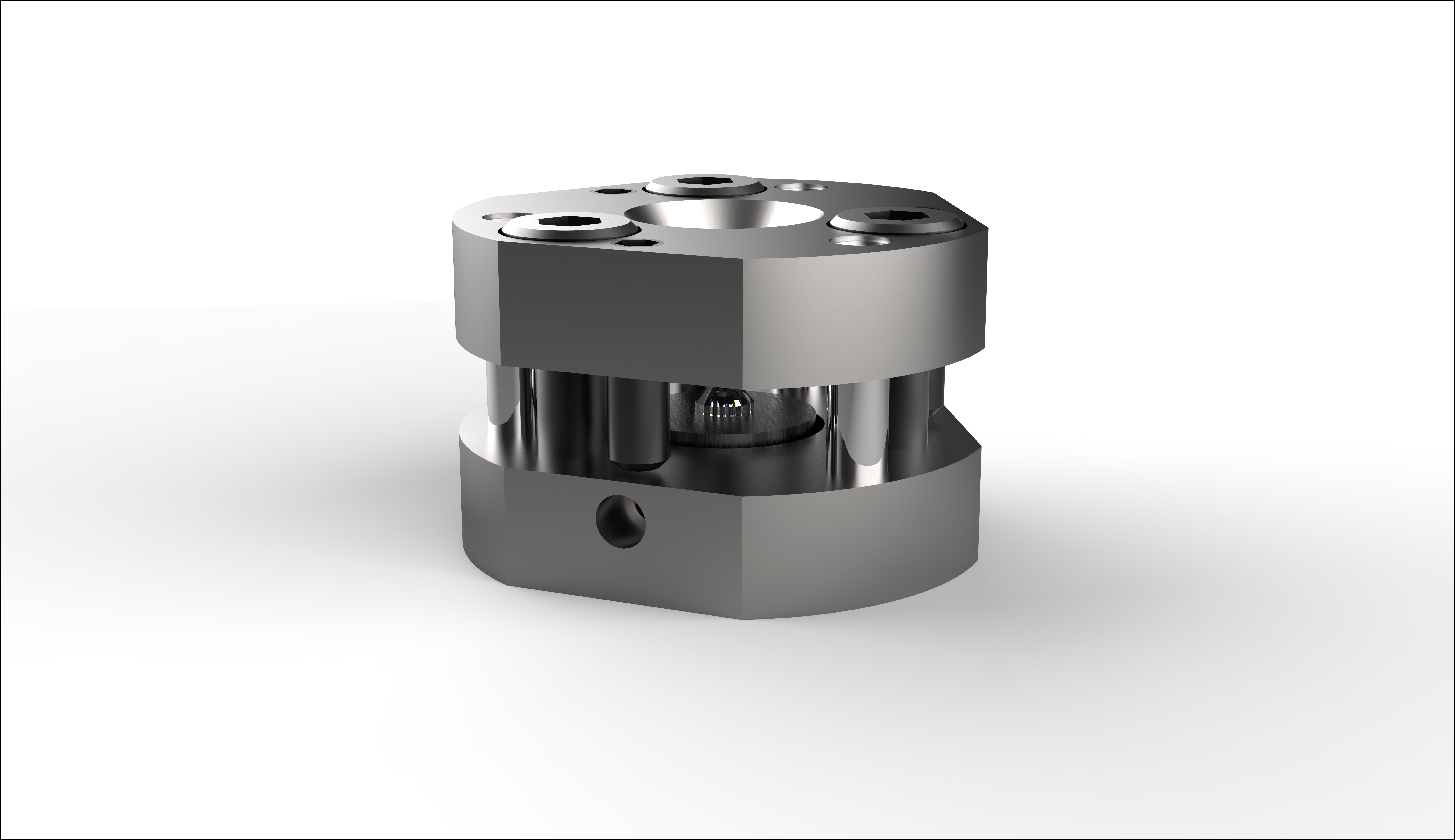

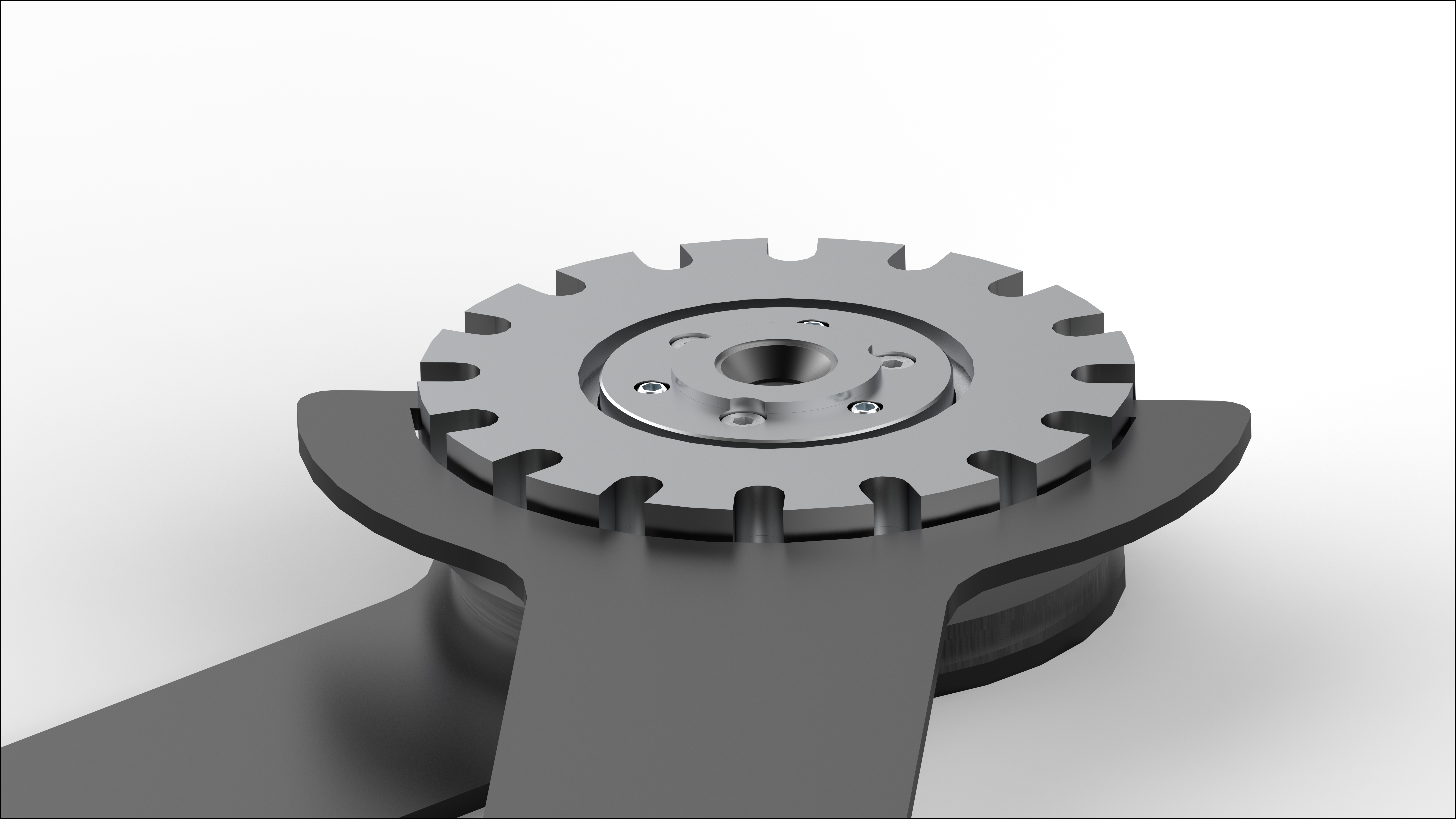

The BX9-HT0 DAC is a diamond anvil cell for high temperature studies. In this model the sample pressure is generated by a gas membrane. It is a DAC with a high-performance heating method, using resistive heaters. One heater is mounted on the external body of the DAC and uses 200 W electrical power to reach sample temperatures up to 800 K. It is suggested to operate the cell inside a vacuum chamber, to prevent the oxidation of materials. Alternatively, to prevent oxidation, it is possible to use the cell in inert gas atmosphere.

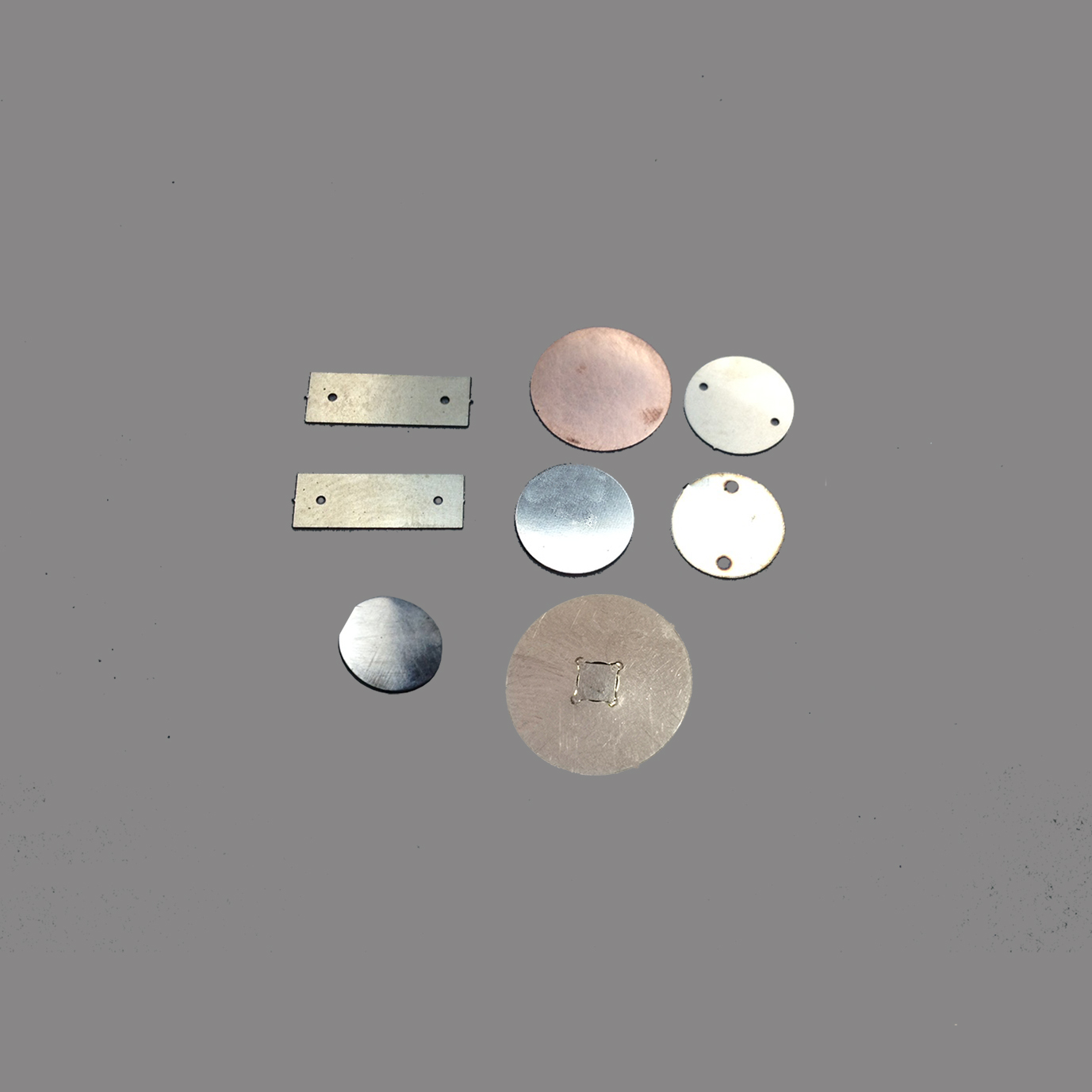

The cell body material, with low thermal expansion, ensures that it can be used up to temperatures of 800 K. A K-type thermocouple mounted close to diamonds is used to control the temperature. A Rhenium gasket allows stable operation of DAC.

To realize the experiment at high temperature it is necessary to monitor the sample pressure to ensure that it do not drop as temperature ramps up. By a remote pressure device the membrane is under constant He gas pressure during the high temperature experiment, providing a continuous constant load, independent of temperature.

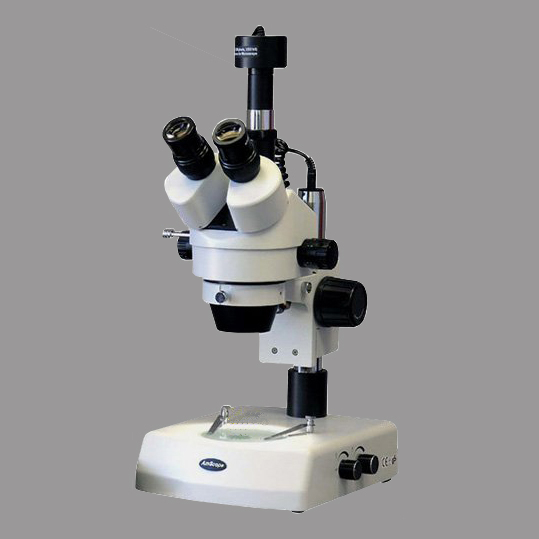

Diamond Anvil Cell technology is nowadays within the reach of even the smallest physics or chemistry laboratory. The simplicity of this device and its affordable price permit any interested scientist to perform measurements at pressures in the 100 GPa range and above. By combining the DAC with different investigation techniques, from the simplest ones, as microscope visual observation, through optical or Infrared spectroscopy, Raman spectroscopy, to synchrotron x-ray scattering, researchers all around the word continues to investigate the changes under pressure of virtually any material. LOTO-eng manufactures a variety of types of DAC, among which, for sure, the one suitable for your purpose. LOTO-eng specialists will help you to identify the most suitable DAC cell, accessories and loading technique to meet your needs, in accordance with your scientific goal and your budget.